Mark Hendry, Head of Technical Support at Hydro Group, said: “These penetrators are the result of client-led feedback on the future requirements of our penetrator ranges, as well as an extensive research, development, and testing process. With a broad operating window of -40°C to 60°C and working voltages of up to 500V, they are ideal for applications in the most demanding of seawater environments. This latest breakthrough means that Hydro Group can meet and exceed current industry depth requirements, due to the increasing trend of employing diving bells and DDCs at more challenging depths than ever before.”

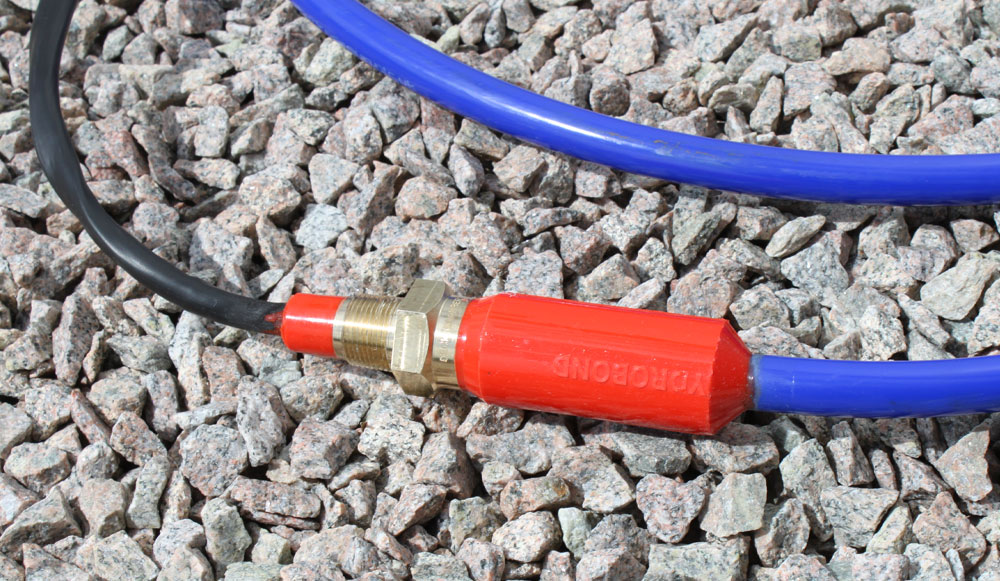

Hydro Group’s range of diving bells and DDC penetrators are available in right angle or in-line moulded configurations.

No less than seven diving bell penetrator types are available in various thread sizes, from 1¾” UNF (Unified Fine) to ½” NPT (National Pipe Thread). A 300V diving bell penetrator is available for the ½” NPT size, with DDC penetrator options including 1” NPT and ¾” NPT.

Samples of each penetrator have undergone rigorous type-tests through the Lloyd’s Register Type Approval scheme, and have successfully been certified by the internationally-recognised quality assurance specialist.

Hydro Group’s technologically-advanced manufacturing facilities in Aberdeen, Scotland enable the company to engineer a catalogue of bespoke and ‘off-the-shelf’ subsea connectivity solutions for defence, oil and gas, and renewable energy industry applications.

Late in 2018, Hydro Group’s contributions to the defence industry were recognised with a visit from Secretary of State for Defence Gavin Williamson MP to the company’s Hydro House headquarters.