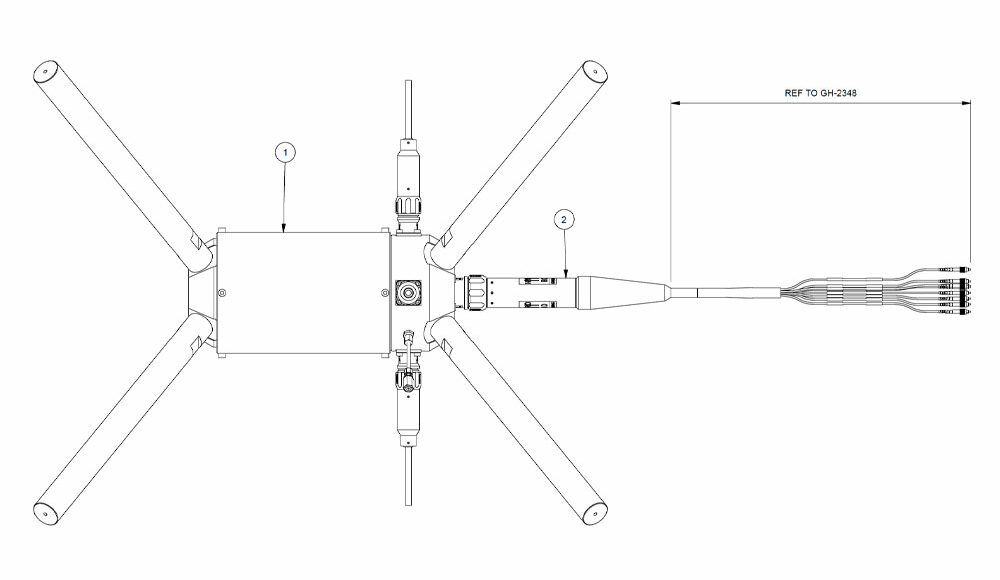

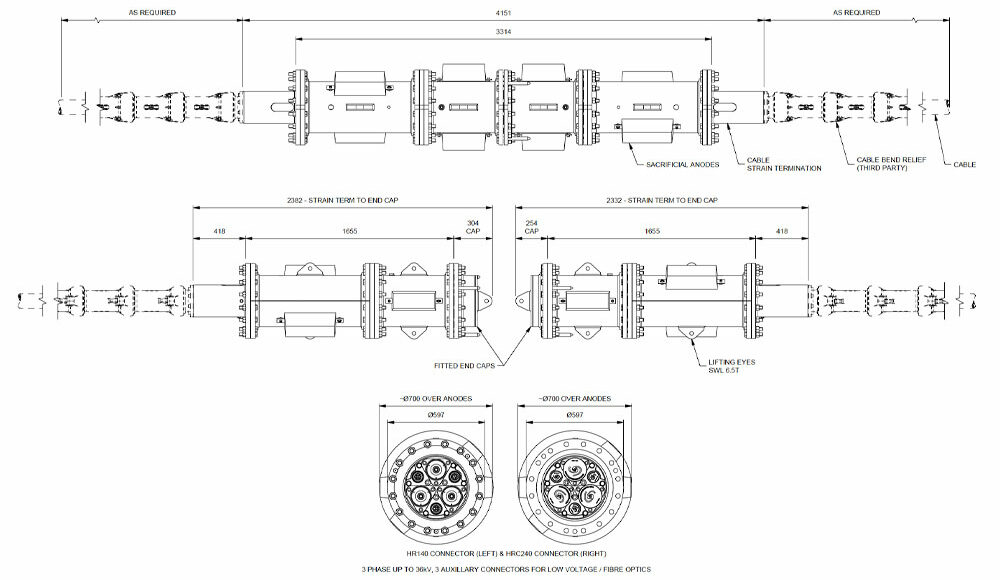

Energy industries generally use umbilical systems to provide electrical power subsea and facilitate high-speed communications to interface between topside and seabed equipment. At the subsea end of these umbilicals are terminations that interface into a range of subsea equipment.

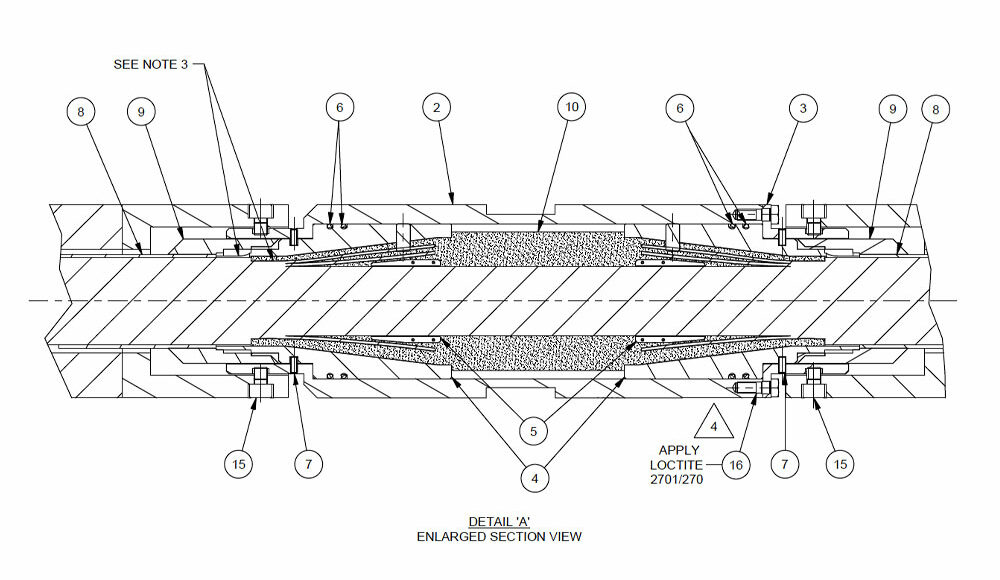

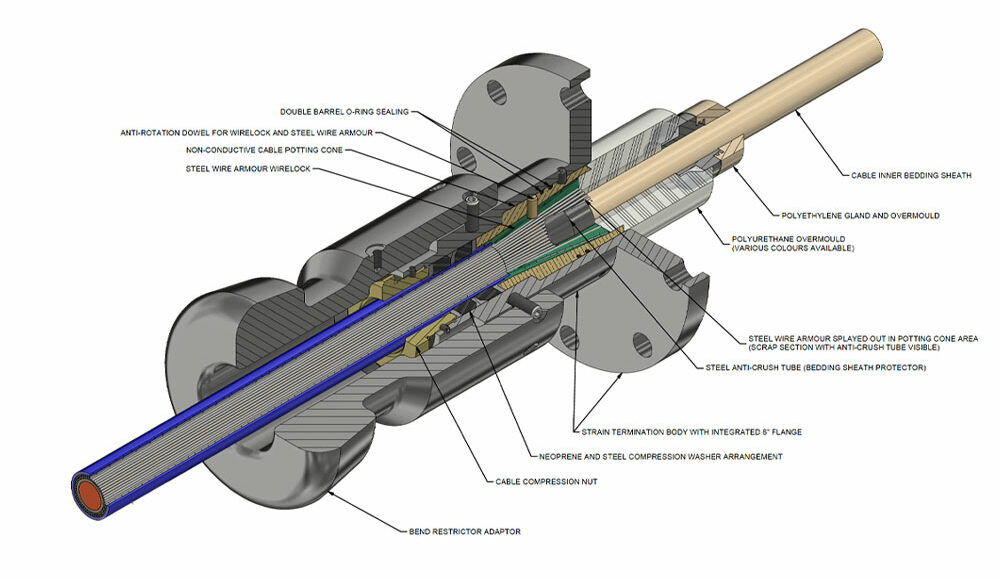

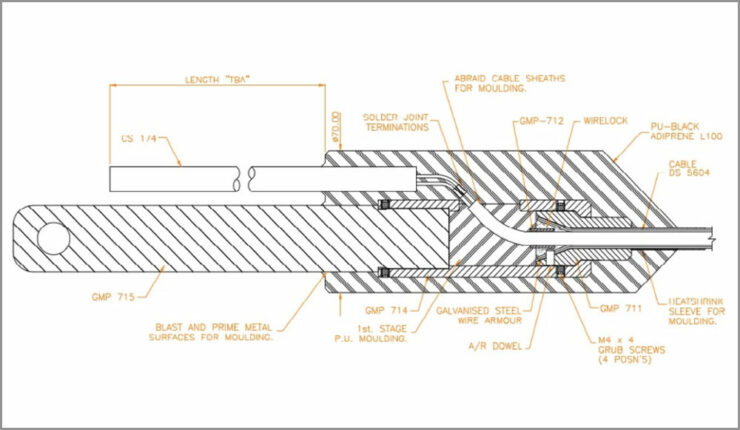

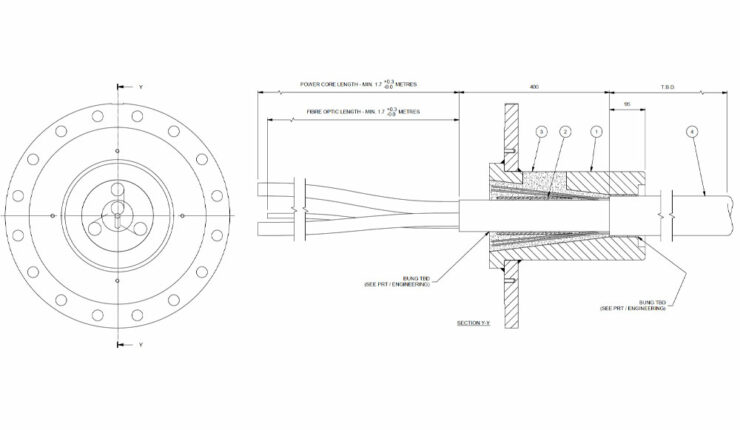

Our strain termination designs range from fairly simple multi-core cables to complex umbilicals containing many cable bundles together with strain and armour members. Water blocking inserts can be incorporated into the design, and in the event of a lead being severed prevent water from spreading from one cable to another. In addition to our standard mechanical strain terminations, we offer bespoke designs to fulfil any customer specifications and requirements. Our design engineering team is respected globally for its high level of industry knowledge and innovation, achieving unique design solutions for challenging subsea applications. Supporting our design department is a professional team of fully trained and equipment certified electrical engineers and technicians.

Our strain terminations have been tested extensively for performance, endurance, and to destruction, both internally and externally by third-party verification companies. Importantly, they have a proven track record over many years on local, national and international projects.

• Designed to suit your working load, subject to the breaking strain of the cable

• Mechanical termination of cable directly to connector back-shell or to bespoke strain bar

• Available with load transferred to outer cable diameter for use with lifting buoys and cable grips

• Customer specified cable break out tail length from main strain termination

• Field Installable designs available

• Full destructive tests available on request

Strain Terminations: Mechanical

Strain Terminations: Mechanical