Head of Sales, Heather Andrade commented … “As a business, we see investing the resource, time and capital in improvement as key to meeting the future needs of our customers, and increasing our ability to bring new innovative products to market.”

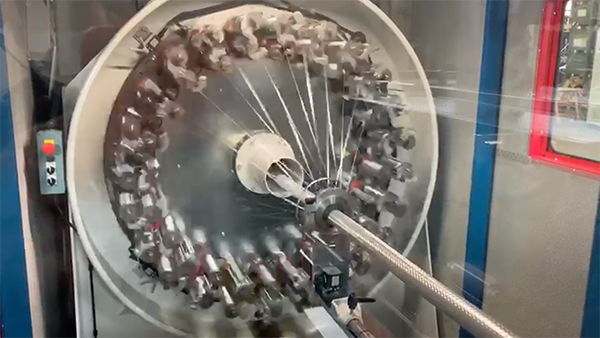

The upgrade to the braiding cell required a complete reorganisation of the current braiding footprint within the facility. The new machine is now capable of handling cable diameters of between 10 and 100mm and can operate at speeds of 5m/minute dependent on the braid design. It allows for high-speed efficient braiding of cables with all types of metallic and fibre braids without joints.

Robert Zielinski, Production Manager Hydro Cable Systems ... “The new braiding line operates at a substantially faster speed than the previous equipment and the new layout allows for greater utilisation of our operators through a multi-machine operation.”

Alongside the braider is a new bobbin winding cell capable of spooling all types of both metallic and fibre braids at speeds of up to 150m/minute

Hydro Group offers a huge range of cable designs featuring fibre braids for towing and lifting applications and metallic braids for abrasion resistance and screening purposes. The new machinery will further enhance capability and reduce lead times.

Developments and Features

• capable of handling cable diameters of between 10 and 100mm

• operates at speeds of 5m/minute dependent on braid design

• high-speed efficient braiding of cables with all types of metallic and fibre braids without joints

• greater utilisation of our operators through a multi-machine operation

• enhance capability and reduce lead times